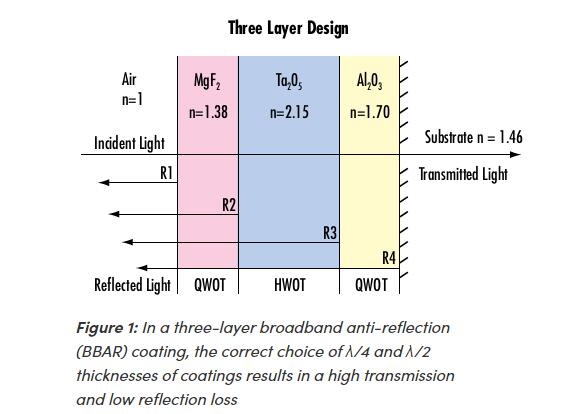

Optical coatings are used to enhance the transmission, reflection, or polarization properties of an optical component. For example, about 4% of incident light will be reflected at each surface of an uncoated glass component. An anti-reflection coating could be applied to reduce the reflection at each surface to less than 0.1% and a highly reflective dielectric coating could also be applied to increase reflectivity to more than 99.99%. An optical coating is composed of a combination of thin layers of materials such as oxides, metals, or rare earth materials. The performance of an optical coating is dependent on the number of layers, their thickness, and the refractive index difference between them. This application note discusses optical coating theory, different types of common coatings, and coating manufacturing methods.

Thin film optical coatings are typically created by depositing dielectric and metallic materials, such as tantalum pentoxide (Ta2O5), aluminum oxide (Al2O3), or hafnium oxide (HfO2), in alternating thin layers. In order to maximize or minimize interference, they are typically λ/4 optical thickness (QWOT) or λ/2 optical thickness (HWOT) of the wavelength of the light used in the application. These thin film layers alternate between high index of refraction and low index of refraction, thereby inducing the interference effects needed (Figure 1).

售前客服

售前客服